LED energy-saving lamps are a new generation of lamps after compact fluorescent lamps. Compared with ordinary energy-saving lamps, LED energy-saving lamps are environmentally friendly and contain no mercury. They can be recycled and reused. They have low power, high luminous efficiency and long life. They are open and bright, resistant to frequent switching, low light decay, rich in color, dimmable, and rich in change. .

Of course, LED energy-saving lamps also have disadvantages, such as: large heat, need to add additional heat sink parts to ensure the normal operation of the LED, in addition, the price is higher when the number of LEDs is higher, and the need to increase the light-transmitting lamp cover to make the light evenly divergent .

This time, disassemble an LED energy-saving lamp (bread light) to see how much the structure inside is different from ordinary energy-saving lamps.

P01 60W LED energy saving lamp (bread lamp)

First, the preparation for dismantling

Main Tools & Materials Preparation

1, LED energy-saving lamps 1

2, screwdriver

3, electric iron, etc.

Second, the process of disassembly

Firstly, the light-transmitting lamp cover of the LED is disassembled, and a large-area aluminum substrate can be seen, and an LED circuit control board is arranged thereon, and the power input is a screw port 220V lamp holder:

P02 Open the lampshade

LED light-emitting surface, 43 groups connected in series after 3 parallel connection, the above 3*43 group LED lamp beads are evenly arranged according to concentric circles:

P03 LED light board

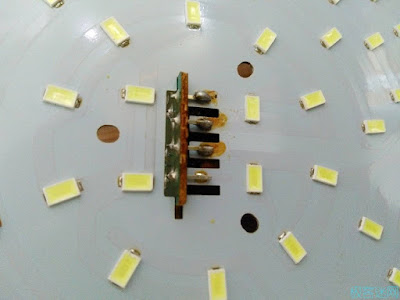

The LED light board is welded to its control board, the middle two are positive and negative, and the other two are auxiliary fixed:

P04 connection

LED control panel:

P05 control panel

The main control chip of the 7Pin pin:

P06 control chip

A close look at the chip model is WS3442D7P:

P07 WS3442D7P

On the back of the LED control board, this PCB is a single-sided printed bakelite:

P08 back solder joint

Use soldering iron to separate the control board from the solder joint of the aluminum substrate:

P09 Remove the control panel

The four connection points on the control board are connected using straight pin welding:

P10 connection point

Remove the back of the control panel:

P11 back

The silkscreen above can be clearly seen:

P12 components & silk screen

At this point, the disassembly is complete, and then the principle is analyzed:

P13 disassembly completed

Third, the principle of disassembly

The WS3442 is a high precision LED constant current control IC for non-isolated step-down LED power systems for a full range of AC voltage inputs or DC voltage inputs from 12V to 500V. The main application areas are LED bulbs and lamps.

WS4332 chip application guide:

P14 WS4332 application

The principle of this LED energy-saving lamp is mainly to use WS4332 as the control chip, and the 220V input AC power is filtered and converted into DC voltage to supply 43 groups of LEDs in series to supply power. The combination method is 3 parallels and 43 sets are connected in series:

The following is a combination of this LED energy-saving lamp:

P15 LED combination

Fourth, there is something to say

After the disassembly of the LED energy-saving lamp, it can be seen that the principle is not complicated. The LED energy-saving lamp controlled by WS4332 is simple in design, and the constant current effect can be realized by adjusting the external resistance value according to the current voltage of different LED lamp groups. The voltage of a single LED lamp bead used in this LED energy-saving lamp ranges from 3.0V to 3.5V, and the power is about 0.5W. According to the calculation of 129*0.5≈64.5W, it meets its nominal power of 60W.

Follow Me

Link:Tenco

twitter:https://twitter.com/TencoTechnology

facebook:https://www.facebook.com/tencotechnology

没有评论:

发表评论